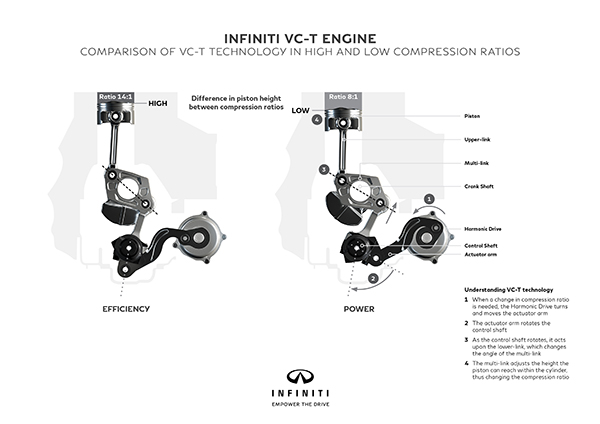

Not too long ago Infiniti just unveiled a first of it’s kind production engine, the Variable Compression Turbocharged engine, or VC-T for short. Up until now production engines have fixed compression ratios, as in the distance between the lowest and highest point of the piston’s travel does not change. What Infiniti did with their VC-T is allow the total stroke of the engine to change resulting in a compression between 8:1 to 14:1, meaning it’s capable of fine tuning the engine to produce somewhere between an “efficiency” and “power” modes. Saab has tried to do something similar but with a different approach. Sadly, they never took it into production.

Infiniti achieved this by adding a multi-link in addition to the regular crankshaft, connecting rod, and piston assembly. In combination with a harmonic drive and actuators, the multi-link is able rotate and change the total travel of the piston. If that sounds a bit too confusing then you should watch the video below as Jason Fenske from Engineering Explained has done a very good job explaining what actually happens inside the VC-T engine. Take a look at the diagram below, watch the video, and learn!

(Source: Engineering Explained)

Leave a reply